Cotton

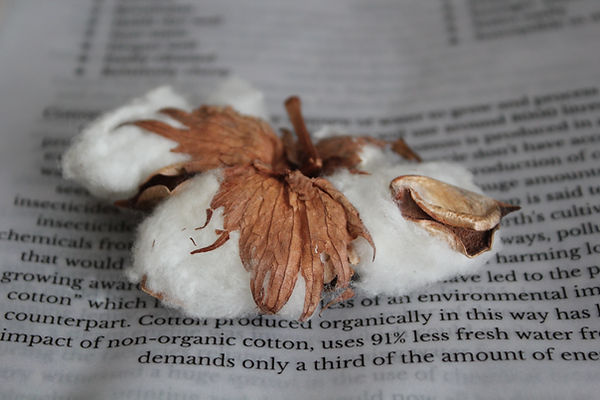

Cotton has been around for centuries, and is an incredibly popular fibre in most households. Most fabrics used to make clothes contain a large percentage of cotton, as do most upholstery fabrics. Cotton is a staple fibre, which means that it is made up of fibres of a range of varying lengths. These fibres come from cotton plants, with the actual part of the plant that is used to make cotton cloth grown inside the boll. Cotton plants are native to tropical regions such as Africa, Egypt, the Americas and India. Nowadays cotton is grown in nearly all tropical regions including the U.S, China, Pakistan, Uzbekistan, Brazil and Turkey, with the United States being one of the largest producers of cotton in the world, alongside India and China.

Pros of using cotton

-

Soft

-

Durable

-

Breathable

-

Holds dye well

-

Non-static

-

Drapes well

-

Easily cleaned

-

Relatively cheap

Cons of using cotton

-

Not fire retardant, burns quickly

-

Wrinkles easily

-

Prone to shrinking when washed

-

Stronger when wet than dry

-

Stains easily

-

Susceptible to mildew

Cotton plants require a large amount of water to grow and process into cloth. Just one pair of jeans that weigh 800 grams will use around 8000 litres of water in its production. To make matters worse, most cotton is produced in areas under high or extreme water stress, where thousands of people don’t have access to safe drinking water. The use of this much fresh water for the production of cotton in these areas seems absolutely ludicrous. Cotton also needs huge amounts of pesticides and insecticides to keep the plants healthy. This needy crop is said to use 16% of the world's insecticides, despite it only covering 2.5% of the earth's cultivated land mass. The chemicals from these products drain into local waterways, polluting any drinking water that would otherwise have been safe for use, and harming local wildlife. However, growing awareness of the impacts of cotton have led to the production of “preferred cotton” which has significantly less of an environmental impact than its traditional counterpart. Cotton produced organically in this way has half the global warming impact of non-organic cotton, uses 91% less fresh water from lakes and rivers, and demands only a third of the amount of energy as well.

Production process

-

The cotton crop is picked by a cotton picker, a machine which picks the whole plant, or alternatively by a cotton stripper which just takes off the boll.

-

Once the cotton has been picked it is balled and stored in the field until its sent to the gins.

-

At the gins, the boll and any other debris are removed and the cotton is cleaned and fluffed.

-

The cleaned cotton is now completely removed from any seeds, and then compressed ready to be sent off to the textile mill for further processing.

-

Here the cotton is put through a carding machine, which further cleans it and forms the short fibres into long untwisted strands, which are ready for spinning and then weaving into cloth.

History

No one knows exactly how old cotton is, but it's been around a very long time. Cotton seeds have been found in India dating back to around 5,000BC, and in the Indus River Valley, cotton was being grown and made into cloth 3,000 years BC. Arabic travellers brought cotton to Europe in around 800 AD, and when Columbus discovered the Americas in 1492, he found cotton plants growing there. By 1500, cotton was known and used throughout the world.

Cotton was first spun by machine in England in 1730, the invention of the cotton gin, and the industrial revolution in England had both sped up the processing of cotton dramatically, and helped to increase its popularity as a commonly used fibre. A gin, short for engine, could separate the cotton from its husk 10 times faster than by hand, allowing larger quantities of cotton to be supplied to the ever growing textile industry. Many of the original cotton factories were based around the north of England, this is because they needed a constant power supply, and were reliant on flowing water to provide this. Later these factories began to be powered by coal, which meant that they were often built closer to coal mines and further from water sources.

Liverpool was an important port for the cotton industry, as this was where much of the raw cotton imported from America was shipped to. Processed cotton cloth was also transported out of England via Liverpool to be transported all over the world. In 733, John Kay invented the flying shuttle, a device that meant that much wider pieces of cloth could be woven faster than ever before. In 1765, James Hargreaves invented the Spinning Jenny, which increased the number of threads each machine could spin. In 1781, a steam engine was invented which could easily be used in a factory setting, reducing the factories reliance on running water for their power. And in the 1800s the industry witnessed a huge spread in the use of chemical bleaches and dyes which meant that bleaching, printing and dying could now all be done in the same factory. All these inventions had a major impact on the production of cotton and its growth in popularity. In 1770 the cotton industry in England was worth £600,000, which increased over the next 100 years to a whopping £38,800,000. No other textile fibre saw such a huge increase in popularity as this, and to this day cotton is still considered a favourite by many.